Journal '%3e%3cmask%20id='mask0_1740_16884'%20style='mask-type:luminance'%20maskUnits='userSpaceOnUse'%20x='0'%20y='0'%20width='10'%20height='10'%3e%3cpath%20d='M10%2010L10%204.37114e-07L4.37114e-07%200L0%2010L10%2010Z'%20fill='white'/%3e%3c/mask%3e%3cg%20mask='url(%23mask0_1740_16884)'%3e%3cpath%20d='M10%2010L10%204.37114e-07L4.37114e-07%200C5.523%202.41418e-07%2010%204.477%2010%2010Z'%20fill='white'/%3e%3c/g%3e%3c/g%3e%3cdefs%3e%3cclipPath%20id='clip0_1740_16884'%3e%3crect%20width='10'%20height='10'%20fill='white'%20transform='translate(10)%20rotate(90)'/%3e%3c/clipPath%3e%3c/defs%3e%3c/svg%3e)

'%3e%3cmask%20id='mask0_1740_16884'%20style='mask-type:luminance'%20maskUnits='userSpaceOnUse'%20x='0'%20y='0'%20width='10'%20height='10'%3e%3cpath%20d='M10%2010L10%204.37114e-07L4.37114e-07%200L0%2010L10%2010Z'%20fill='white'/%3e%3c/mask%3e%3cg%20mask='url(%23mask0_1740_16884)'%3e%3cpath%20d='M10%2010L10%204.37114e-07L4.37114e-07%200C5.523%202.41418e-07%2010%204.477%2010%2010Z'%20fill='white'/%3e%3c/g%3e%3c/g%3e%3cdefs%3e%3cclipPath%20id='clip0_1740_16884'%3e%3crect%20width='10'%20height='10'%20fill='white'%20transform='translate(10)%20rotate(90)'/%3e%3c/clipPath%3e%3c/defs%3e%3c/svg%3e)

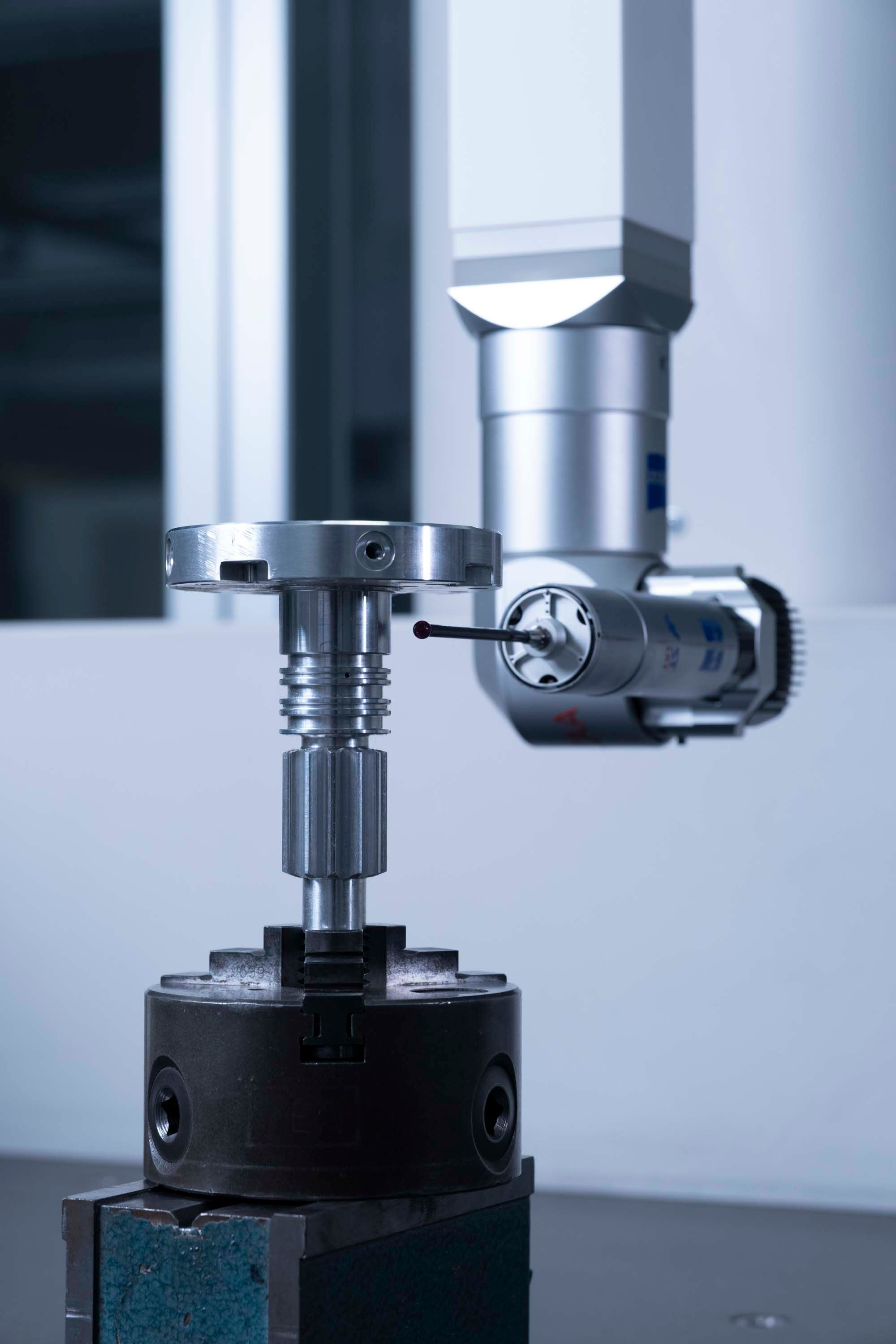

Quality Control: Where Precision Becomes Culture

17.10.2025

Excellence is measured in microns and mindset. Every inspection reflects the craftsmanship, discipline, and trust that define Gimatic.

At Gimatic, quality is not a final step — it is the foundation of everything we create. From the first design sketch to the final assembly, every component follows a path defined by measurement, verification, and care. Within our ISO 9001-certified facilities, precision is both a science and a philosophy.

Coordinate measuring machines and Zeiss optical systems verify tolerances as fine as 0.02 millimeters, ensuring absolute repeatability across every batch. Our inspection rooms are climate-controlled environments where geometry, performance, and material consistency are continuously monitored and maintained. But the heart of our quality control lies not only in machines — it lives in the hands and minds of our people.

Experienced technicians, trained to interpret the subtleties of each component, approach inspection as a craft. They listen to the rhythm of production, understand the language of materials, and apply intuition where algorithms end. This human insight transforms control from a mechanical task into an act of refinement.

Every stage — from raw material selection to final EOAT assembly — is tracked, documented, and analyzed through digital traceability systems. This ensures consistency over time and complete transparency for both internal teams and our global partners.

For Gimatic, quality is not about achieving perfection once; it’s about repeating it endlessly. It’s the invisible thread that connects innovation, responsibility, and trust.

Because true excellence is not measured only by precision, but by the discipline, curiosity, and integrity that sustain it, quality, at Gimatic, is more than a promise; it’s a culture we build, one component at a time.