Innovation Hub '%3e%3cmask%20id='mask0_1740_16884'%20style='mask-type:luminance'%20maskUnits='userSpaceOnUse'%20x='0'%20y='0'%20width='10'%20height='10'%3e%3cpath%20d='M10%2010L10%204.37114e-07L4.37114e-07%200L0%2010L10%2010Z'%20fill='white'/%3e%3c/mask%3e%3cg%20mask='url(%23mask0_1740_16884)'%3e%3cpath%20d='M10%2010L10%204.37114e-07L4.37114e-07%200C5.523%202.41418e-07%2010%204.477%2010%2010Z'%20fill='white'/%3e%3c/g%3e%3c/g%3e%3cdefs%3e%3cclipPath%20id='clip0_1740_16884'%3e%3crect%20width='10'%20height='10'%20fill='white'%20transform='translate(10)%20rotate(90)'/%3e%3c/clipPath%3e%3c/defs%3e%3c/svg%3e)

'%3e%3cmask%20id='mask0_1740_16884'%20style='mask-type:luminance'%20maskUnits='userSpaceOnUse'%20x='0'%20y='0'%20width='10'%20height='10'%3e%3cpath%20d='M10%2010L10%204.37114e-07L4.37114e-07%200L0%2010L10%2010Z'%20fill='white'/%3e%3c/mask%3e%3cg%20mask='url(%23mask0_1740_16884)'%3e%3cpath%20d='M10%2010L10%204.37114e-07L4.37114e-07%200C5.523%202.41418e-07%2010%204.477%2010%2010Z'%20fill='white'/%3e%3c/g%3e%3c/g%3e%3cdefs%3e%3cclipPath%20id='clip0_1740_16884'%3e%3crect%20width='10'%20height='10'%20fill='white'%20transform='translate(10)%20rotate(90)'/%3e%3c/clipPath%3e%3c/defs%3e%3c/svg%3e)

Test Room: Where Every Movement Proves Its Perfection

02.09.2025

Every cycle tells a story of endurance and precision, testing innovation until performance becomes perfection.

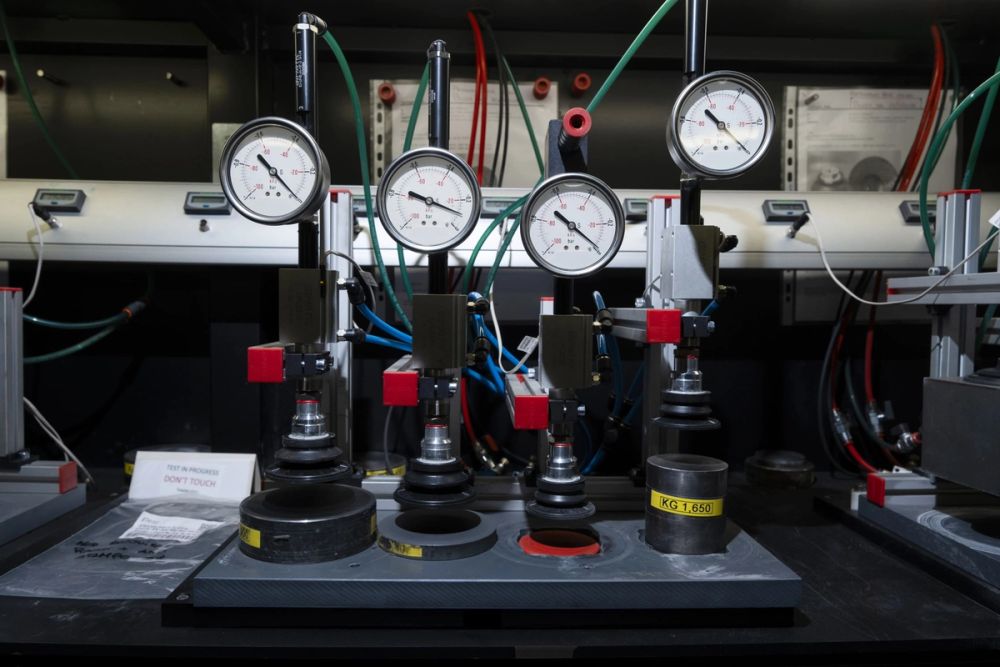

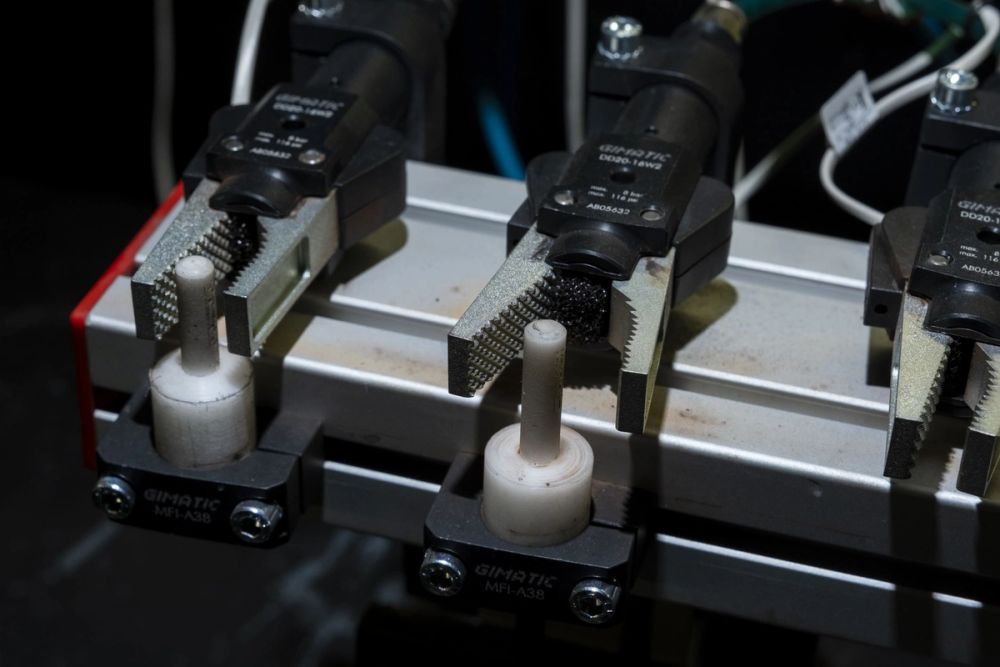

Before reaching the world, every Gimatic component must first prove itself — inside our dedicated Test Room. This is where precision becomes performance: a controlled environment where products are pushed to their limits through endurance, vibration, temperature, and load testing.

Here, pneumatic and electric grippers are tested for millions of cycles, validating durability, repeatability, and energy efficiency. Sensors and mechatronic systems undergo real-time feedback simulations, verifying response accuracy and stability under the most demanding conditions. Each result feeds directly into our R&D process, closing the loop between design, production, and validation.

Our testing protocols adhere to international standards and exceed compliance requirements. We measure not only what a product can do, but how it behaves over time — ensuring consistency, reliability, and elegance in motion. Specialized benches replicate real-world scenarios across multiple industries, including automotive, packaging, medical, and electronics, providing seamless integration with robots and automated systems.

Inside the Test Room, data meets craftsmanship. Engineers interpret readings like artisans, fine-tuning every curve, grip, and movement until function and form align perfectly. It’s a process guided by experience, precision, and the same human sensibility that defines every Gimatic solution.

Because testing, for us, is not the final step — it’s part of creation itself. Every movement, every click, every cycle tells a story of confidence, proving that perfection is not assumed, but earned.